Step-change performance in anti-corrosion treatments together with new processing capability and more productive coating manufacturing lines.

Step-change performance in anti-corrosion treatments together with new processing capability and more productive coating manufacturing lines.

Academic: Nick Birbilis (Deakin)

Industry: Simon Correnti (BlueScope)

Several important fundamental challenges in the development and manufacture of next-generation metallic coated products are addressed in this research program. The industry will benefit significantly from the proposed advances in fundamental understanding relating to corrosion mechanisms, novel corrosion assessment of coated products and innovations that substantially increase the overall manufacturing efficiency of continuous hot-dip coating process and coating equipment.

Outcomes of this multi-faceted research program will lead to a step-change performance in anti-corrosion treatments for metallic coatings, leading to potentially new processing capabilities, as well as more productive, efficient coating manufacturing lines.

Program 3 is comprised of two sub-programs:

- Corrosion Performance and Prediction

- Coatings Process Effectiveness

This project has been designed to be a highly collaborative effort across university partners (University of Wollongong, Monash University, Australian National University and Deakin University) and BlueScope Limited (BSL).

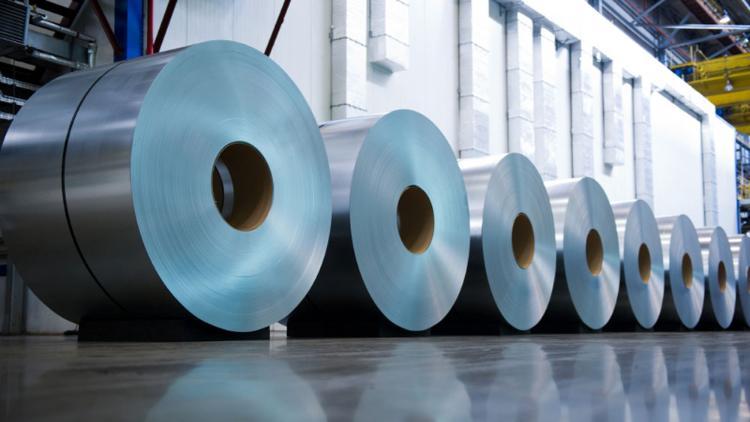

Coated steel products, including bare alloy coated and organic coated (pre-painted) materials, are an important component of BSL’s product portfolio. Research and development regarding the durability of these coated products creates opportunity to better understand existing products, including their predicted lifespan, and the prospects for scientific understanding of performance, that is core to the development of improved or novel products.

Contemporary state-of-the-art facilities will be utilised in order to better assess existing coatings, assess their life prediction, and the development of new coatings in terms of design and process. Fundamental and mechanistic based analyses will permit developments that will have both near and long-term implications.

To achieve these goals, a multi-disciplinary approach that covers experiments and modelling has been broken into three core themes: improved corrosion assessment; coated product corrosion and modelling; and coated product passivation and modelling.

Team: Professor Nick Birbilis (Deakin), Dr Azdiar Gazder (UOW), Dr Sebastian Thomas (MON), Simon Correnti (BlueScope), Andrew Collins (BlueScope), Kateryna Gusieva (BlueScope), Thomas Jurak (BlueScope), Jason Hodges (BlueScope), Dr Majid Laleh (UOW), PhD candidate Shujing Zhao (ANU)

This project will focus on the development of an IoT sensing system for onsite monitoring of environmental variables that are responsible for corrosion. The research activities are coupled with the broader research investigation within Project 3.1: Coatings, Corrosion Protection and Prediction.

BlueScope conducts a large corrosion assessment program for bare alloy and organic coated (pre-painted) steel products using a combination of real-world outdoor (washed, unwashed &sheltered) and laboratory-based accelerated (Q-Fog CCT-1 and ASTM B-117) corrosion exposure methods. Project 3.1a will collect higher-resolution quantitative environmental data from these exposure environments. Such data should also support the broader investigation in Project 3.1.

Team: Dr Cormac Fay (UOW), Dr Thomas Jurak (BlueScope), Andrew Collins (BlueScope), Elliot Pilton (UOW)

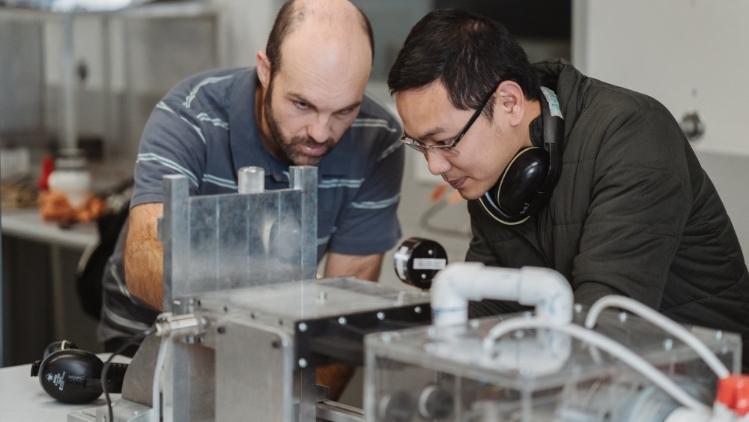

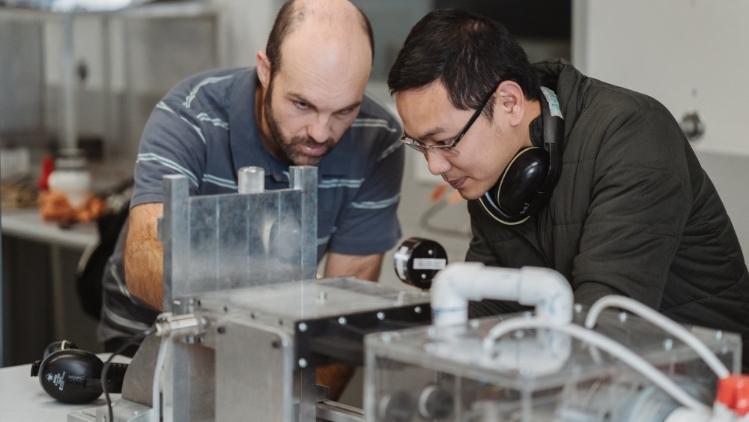

Bringing together the expertise from the University of Wollongong (UOW) and BlueScope Limited (BSL), this project aims to minimise the surface abnormalities in the production of metal coated steel strips.

Jet wiping is essential in the process in production of thin galvanised coating on steel strip. Understanding of the fluid dynamics of the jet and the coating and their interactions that cause irregular coating surfaces will assist BSL in improving the productivity of the plants producing products with heavy coating at low speed, by tuning the process operational parameters and design of auxiliary jet wiping equipment.

Team: Professor Buyung Kosasih (UOW), Dr Andrew Johnstone (UOW), Chris West (BlueScope), Wayne Renshaw (BlueScope), Simon Correnti (BlueScope), Dr Andrew Dixon (UOW), PhD candidate

This collaborative University of Wollongong (UOW) and BlueScope Limited (BSL) project, focuses on the surface engineering of materials for increased resilience in aluminium-zinc (Al-Zn) metal coating baths.

The findings of this research will lead to improved understanding of the fundamental reactions between materials and molten coating metal, the development of coating materials for immersed pot hardware, techniques and expertise in Zn-Al bath management practices that extend functional pot life of components.

Team: Associate Professor Yue Zhao (UOW), Dr Joe Williams (BlueScope), Dr Nega Setargew (BlueScope), Simon Correnti (BlueScope), PhD candidate Xialan Liu (UOW)

Image credit: Craig Holbrook