February 18, 2026

Researchers achieve world-first in underwater 3D concrete printing

LUYTEN 3D collaboration produces Australia’s first submerged 3D printing system, world-first accelerator-free concrete mix for use underwater

University of Wollongong (UOW) researchers have partnered with construction technology company LUYTEN 3D to achieve Australia’s first underwater 3D concrete printing system, and the world’s first “single-mix” concrete formulation that sets and builds stably underwater without chemical accelerators.

“Our trials confirm that our single-mix solution is not just theoretically sound but practically viable. It offers the structural integrity needed for real-world application while simplifying the logistics of underwater deployment,” UOW project lead Dr Aziz Ahmed said.

The breakthrough challenges conventional underwater construction, which typically relies on multi-stage systems or rapid-setting chemical accelerators to stop concrete washing out. The UOW–LUYTEN team’s accelerator-free mix achieves stability through smart material design alone, making it simpler and safer to deploy. The technology enables structures to be built or repaired directly on-site underwater, reducing the need for costly dry docking, marine works or extended shutdowns.

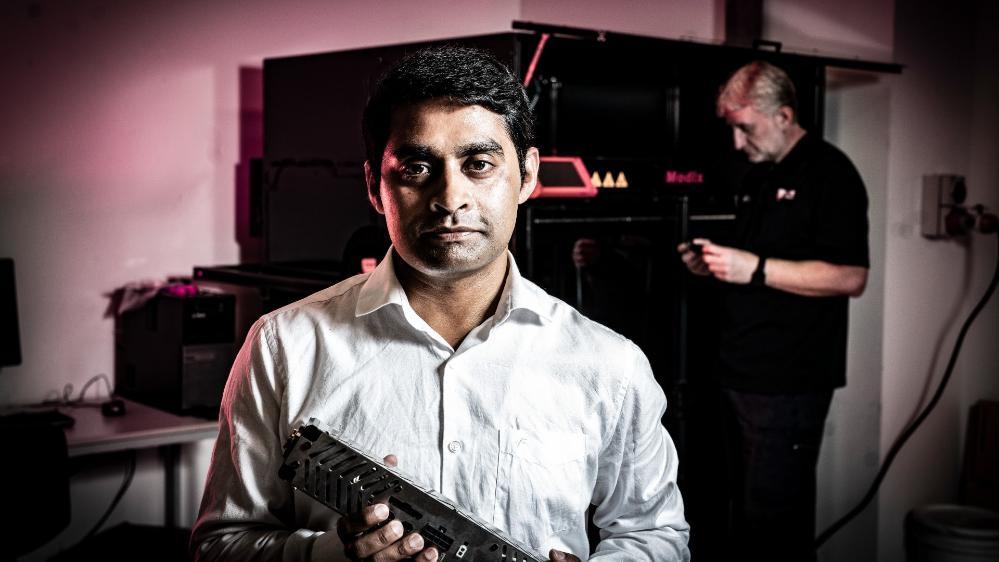

Dr Aziz Ahmed from UOW’s School of Engineering worked alongside structural engineering expert Professor Neaz Sheikh and Research Fellow Dr Sheikh Sakib. Marine biologist Professor Emeritus Andy Davis and Blue Economy researcher Dr Freya Croft are investigating the ecological and community dimensions of the technology, ensuring it is environmentally responsible and socially supported.

The technology has immediate applications in defence, ports and coastal infrastructure – including potential use in the AUKUS submarine program and the construction of sustainable anchors for floating offshore wind farms. As Australia confronts ageing maritime infrastructure and increasing climate pressures, the team sees the work as a platform for future innovation, including research into construction techniques for extraterrestrial environments.

“The successful demonstration is a testament to the high calibre of our engineering talent and world-class laboratories. Our team has solved a complex material science problem, eliminating chemical accelerators without sacrificing stability, showing the depth of expertise within the School of Engineering,” said Senior Professor Gursel Alici, Executive Dean of the Faculty of Engineering and Information Sciences.

“Printing underwater fundamentally changes how we think about building, repairing and strengthening critical infrastructure in marine environments. This is a completely new chapter for construction and manufacturing,” said Ahmed Mahil, CEO and Global President, LUYTEN 3D.