February 4, 2020

$2.15 million investment in NSW’s fabrication future

Funding will boost research and commercialisation of advanced materials and 3D printing at UOW

The Australian National Fabrication Facility (ANFF) has been awarded $2.15 million by the New South Wales Government’s Office of the NSW Chief Scientist and Engineer to invest in six sites across the state.

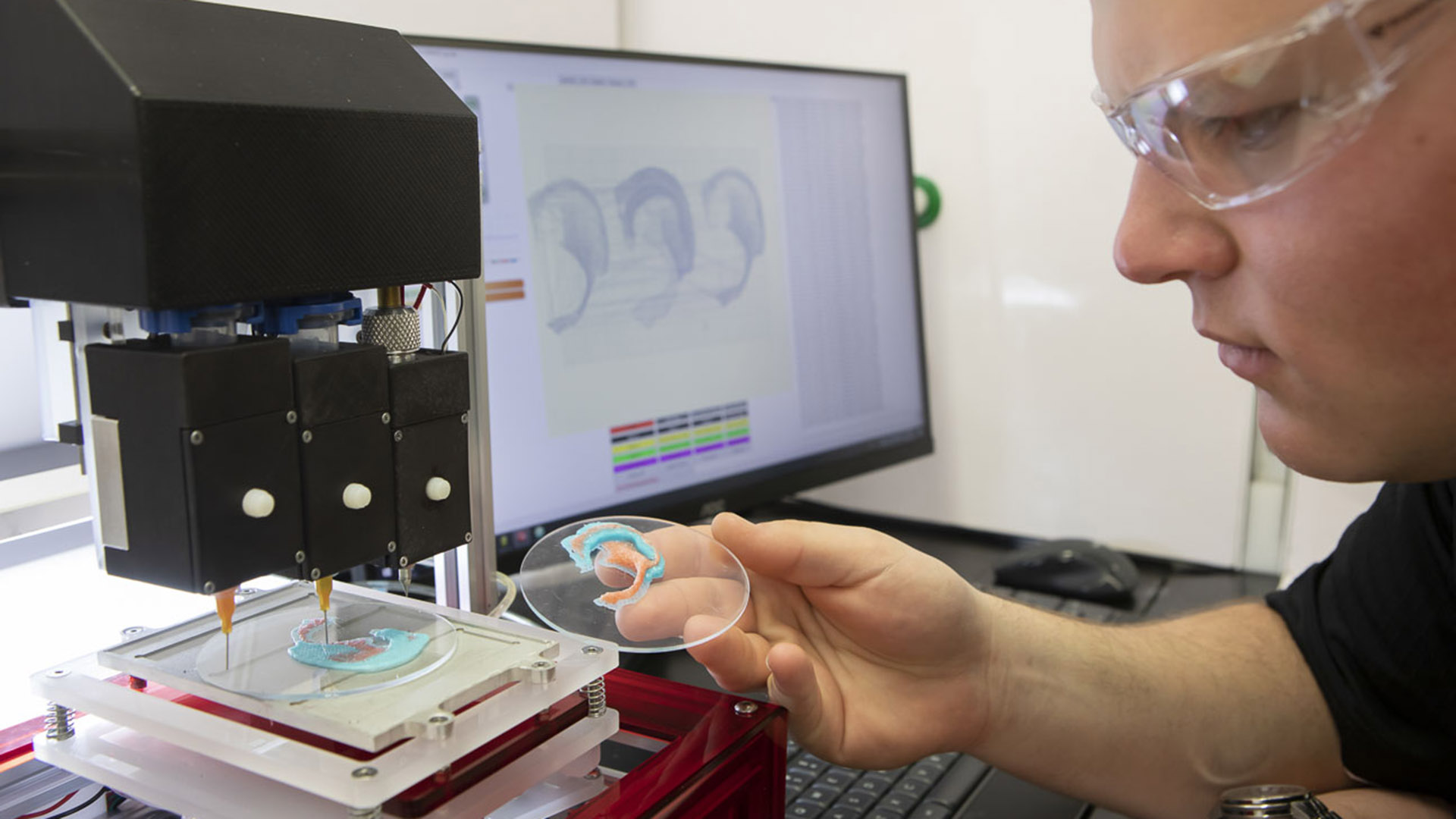

The ANFF Materials Node, headquartered at the University of Wollongong, will benefit from this investment, to strengthen the facility’s advanced materials process, 3D printing and 3D bioprinting capabilities.

ANFF Materials Node Director Distinguished Professor Gordon Wallace said this funding will assist the team to take the next steps towards manufacturing commercial opportunities through advanced materials and 3D printing.

“For the ANFF Materials Node, this announcement unlocks access to state-of-the-art materials synthesis and fabrication equipment,” Professor Wallace said.

“These procurements will ensure we stay at the forefront of global advances in new materials and their deployment in devices for energy and medical technologies.”

The funding arrives through the Research Attraction and Acceleration Program (RAAP), a biennial NSW Government program that provides investment in infrastructure.

It will be used to complement support provided by the National Commonwealth Research Infrastructure Strategy (NCRIS) in 2018 – which totalled $36.6 million in the national ANFF network – as well as significant funds from the six NSW universities that offer ANFF equipment.

ANFF CEO Dr Ian Griffiths said this NSW Government support is essential to the research communities of not just Sydney, Wollongong, Macquarie, and Newcastle, but across the country and abroad.

“It is by enhancing networks such as ANFF and NCRIS that these locations can provide platforms for collaboration between industry and academia and to help promising technologies to transform into new products, companies, and jobs,” Ian said.

“This funding will help ANFF to build and maintain the critical mass of infrastructure and expertise that attracts international interest from globally recognised leaders in their field.”

ANFF provides open access to micro and nanofabrication equipment and expertise at 21 locations across Australia. Six of these locations are embedded with NSW universities: the University of Wollongong; the University of Newcastle; the University of New South Wales; the University of Technology Sydney; the University of Sydney; and Macquarie University.

These sites assist academics, start-up companies and international technology leaders as they pursue cutting-edge research projects.

Plans for expansion of ANFF’s capabilities in NSW that will leverage this funding including the building of industry-standard process lines to assist the commercialisation of novel semiconductor products, bioprinting, and quantum technologies; to enhance additive and subtractive manufacturing suites; and to acquire or upgrade advanced patterning, etching, and deposition equipment for specific materials, including diamond.

This is in addition to supporting the operating costs of hundreds of pieces of existing equipment, approximately 40 staff, and a network of open access laboratory and clean room spaces that are used by hundreds of researchers and engineers each year.

Over the past few years, micro and nanofabrication capabilities available in NSW have been used to set a string of quantum computing records that have helped Sydney become a world-leading quantum hub; support internationally recognised expertise in the 3D printing of biological material for clinical applications; develop printable solar panels that could turn struggling printing companies into manufacturers of affordable clean energy technologies; and produce award winning communication technologies that could speed up download speeds without having to replace existing infrastructure.