August 16, 2021

Swinburne and InfraBuild Launch Two New I4.0 Collaborations

The Steel Research Hub is excited to kick off two more projects which bring together experienced teams from Swinburne University of Technology (SUT) and Infrabuild (Manufacturing) to help further implement Industry 4.0 technologies in Australian steel manufacturing plants.

Infrabuild (Manufacturing) is the largest integrated manufacturer and supplier of steel long products and solutions, and one of the largest metals recycling businesses in Australia. As a LIBERTY Steel Group brand, and part of the GFG Alliance, they are working towards creating a more sustainable future for industry and society, and contributing to GFG Alliance’s mission to become Carbon Neutral by 2030 (CN30).

The two new Steel Research Hub projects will focus on: the development and analysis of sound sensor technology for advanced control of steel ladles and data-driven solutions for improving the consistency of steel products at the Billet Caster.

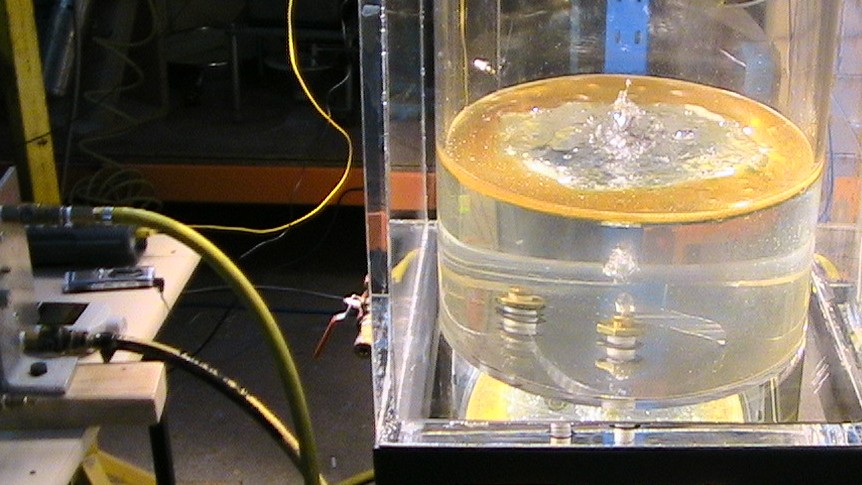

In the project “Development of Sound Sensors for Control of Ladle Metallurgy”, InfraBuild (Manufacturing) aims to drive Industry 4.0 adoption across its steelmaking plants, by incorporating new sensor technology into their advanced control systems and hence, improve their steel ladle station operations. This project draws on promising results from SUT’s previous work, which was based on physical modelling and plant trials using microphone systems. Further work is required to develop and establish a fully functioning commercial system for measuring stirring in steel ladles.

The Project team consists of SUT’s Project Leader, Geoffrey Brooks and Associate Researchers, Michelle Dunne and David Sly, and Infrabuild’s Technical Superintendent Rod and Bar, Andrea Fontana, and Associate Researchers, Steven Grundy and Alister King. The team draws together significant experience in advanced steel-related research, and industrial development/deployment. A Post-Doctoral Research Fellow will be employed to undertake the main research activities, including the delivery of expected plant trials.

In the project “Big Data Analytics for Billet Caster Control in EAF Steelmaking”, the team will develop novel IoT and AI technologies, which will use data drawn from production machines, steel products and plant operators, to improve the overall consistency of steel billet products.

The Project Team, consisting of SUT’s Project Leader, Dimitrios Georgakopoulos and Research Fellow, Abhik Banerjee, and Infrabuild’s Technical Superintendent Rod and Bar, Andrea Fontana and Associate Researchers, Andrew Thomas, Lewis O’Neill and Callum McVeigh, brings together substantial skills in enabling technology research and industrial implementation to drive industrial transformation and efficiency. A Post-Doctoral Research Fellow will be employed to drive the delivery of the research outcomes and will jointly supervise and train a new PhD candidate.

The Steel Research Hub looks forward to reporting of many success stories from these two new SUT-Infrabuild (Manufacturing) projects designed to enable the futureproofing of Australian steel manufacturing through the adoption of Industry 4.0 principles within this vital industry.