May 1, 2018

Material to help transition to clean hydrogen fuel

Compound used in sunscreen a catalyst for low-cost, high-performance water splitting

The ability of plants to harvest sunlight and split water into hydrogen and oxygen through photosynthesis has long fascinated scientists, who have sought to replicate the process to capture hydrogen as a renewable and sustainable fuel source.

Despite its promise, wide-scale use of hydrogen is restricted by cost and efficiency in its extraction processes, which requires an energy input to reverse the reaction that combines oxygen and hydrogen in the first place.

One method is electrolysis, where an electrical current is applied to water by inserting two electrodes and the chemical bond between the hydrogen and oxygen atoms is broken.

This releases the hydrogen as a gas that can be captured and converted to electrical energy in a fuel cell, where the only byproducts from its use are heat and water.

The challenge for scientists is to find a catalyst to drive electrolysis that requires less energy than is gained from the resulting hydrogen.

Complicating matters is that the materials used in electrolysis start to corrode when a current is applied, requiring the use of noble metals, such as platinum, gold or silver.

These are expensive and rare metals that are typically used in electronics, medicine and as catalysts for chemical reaction.

Catalytic challenges

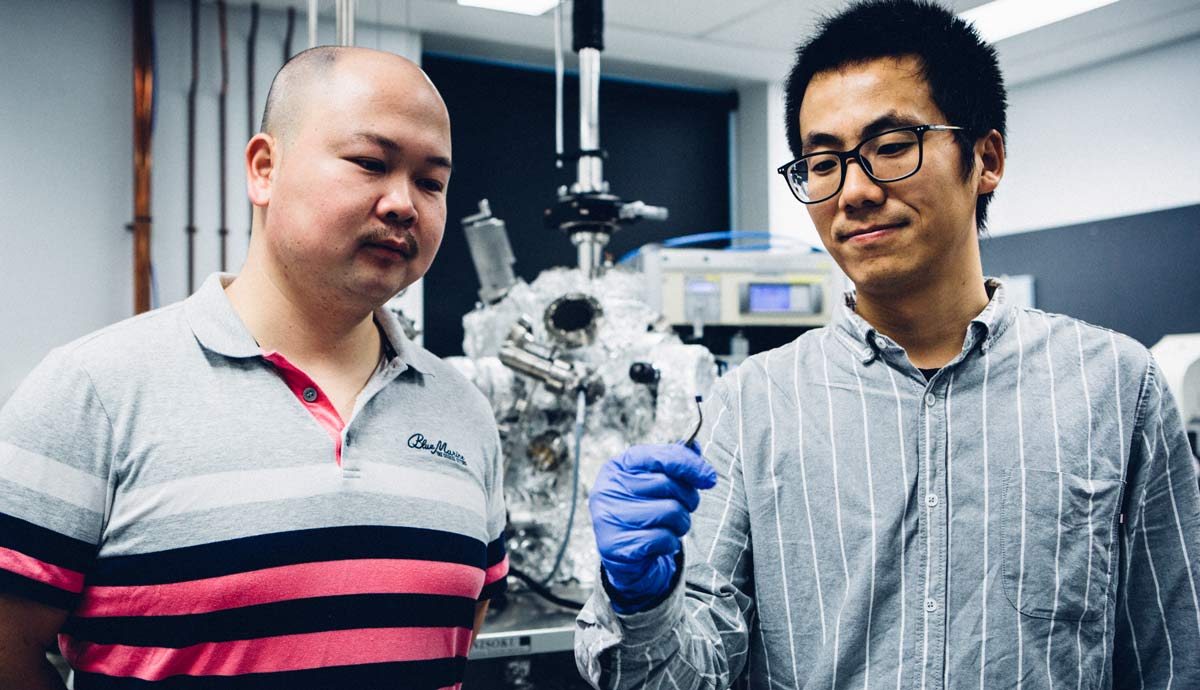

Dr Yi Du, a Senior Research Fellow at the University of Wollongong’s Institute for Superconducting and Electronic Materials (ISEM), said the biggest challenge in industrial-scale water splitting is finding highly efficient, low-cost and earth-abundant electrocatalysts, which can lower the voltage needed to split water into hydrogen.

“Water is a clean source that can be sustainably accessed, which makes it an attractive and promising substitute for liquefied petroleum gas if we can lower the demanded energy to split water,” Dr Du said.

“Generally speaking, there are few electrocatalysts to make hydrogen production cost-effective enough for use on a commercial scale.”

Dr Du’s team at ISEM, in a collaboration with researchers at Beihang University in China, have fabricated a high-performance electrocatalyst using a low-cost metal that is proving suitable for use in water splitting.

Titanium-oxides are an abundant raw material commonly found as a white powder in ores, sands and soils, and often used as pigments in products such as sunscreen, cosmetics, paints and adhesives, among other uses.

While titanium has excellent corrosion resistance and electrical conductivity, in its oxide it is an insulator, and researchers have long thought it unsuitable for use as an electrocatalyst.

Dr Du’s team were able to take a single crystal of titanium oxide and in a vacuum chamber, remove all the oxygen atoms from the surface, leaving a conductive, durable and efficient catalyst material that is cheap and easy to produce

“Compared to a traditional catalyst, the conductive titanium oxide requires very little energy input to drive the electrolysis water splitting process,” Dr Du said.

“By introducing a large number of oxygen vacancies in the surface of the material we can optimise its physical and chemical properties to be active for water splitting.

“We’ve demonstrated that a series of earth-abundant, low-cost and chemically stable materials based on titanium are promising electrocatalysts in water splitting, which may greatly reduce the cost of this technique and accelerate large-scale use.”

Zero-emissions energy potential

If the electrical energy to power the reaction is also sourced from renewable generation, the process has the potential to be close to energy neutral.

“There are quite a few applications for using this fuel, perhaps the most promising application is large-scale water splitting to power factories that have high energy demands,” Dr Du said.

Hydrogen can be converted to electrical energy through fuel cells that can operate continuously in the presence of hydrogen and oxygen.

“Use of solar cells to harvest energy to power the process is also a promising way of producing hydrogen sustainably with zero emissions for use in transport via hydrogen fuel cell vehicles.”

While grabbing the garden hose to fuel the car might seem like science fiction, Dr Du said the fundamental challenges on the production side of the hydrogen equation were cost and efficiency.

“The biggest challenge is still the cost of the catalyst. That’s why we need an efficient and cheap catalyst, which can convert water to hydrogen effectively.”

The work was published recently in the journal ACS Catalysis and is based on collaboration with Beihang University via the Beihang-UOW Joint Research Centre.