[1] Latifi, A., 2021. Housing Trust CEO calls for federal budget cash to fix rental housing crisis. The Illawarra Mercury, [online] Available at: <https://www.illawarramercury.com.au/story/7245268/3500-affordable-rental-homes-needed-in-the-illawarra-to-fix-housing-crisis [Accessed 29 November 2021].

[2] Australian Institute of Health and Welfare. 2021. Indigenous housing - Australian Institute of Health and Welfare. [online] Available at: https://www.aihw.gov.au/reports/australias-welfare/indigenous-housing [Accessed 29 November 2021].

[3] Australian Bureau of Statistics. 2021. Waste Account, Australia, Experimental Estimates, 2018-19 financial year. [online] Available at: https://www.abs.gov.au/statistics/environment/environmental-management/waste-account-australia-experimental-estimates/latest-release#data-download [Accessed 15 October 2021].

[4] Tractile. 2021. Tractile - The Premium Roofing Company. [online] Available at: <https://tractile.com.au/> [Accessed 1 December 2021].

[5] Aquacomb. 2021. Aquacomb - Innovative Water Solutions. [online] Available at: <https://www.aquacomb.com.au/> [Accessed 1 December 2021].

[6] Conceptosplasticos-com.translate.goog. 2021. Conceptos Plásticos - Productos. [online] Available at: https://conceptosplasticos-com.translate.goog/conceptos-plasticos.html?_x_tr_sl=es&_x_tr_tl=en&_x_tr_hl=en&_x_tr_pto=nui,sc [Accessed 29 November 2021].

[7] Asdrubali, F., D'Alessandro, F. and Schiavoni, S., 2015. A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies, [online] 4, pp.1-17. Available at: https://www.sciencedirect.com/science/article/pii/S2214993715000068 [Accessed 27 August 2021].

[8] Durra Panel. 2021. Durra Panel Benefits. [online] Available at: https://durrapanel.com/benefits/ [Accessed 29 November 2021].

[9]"What is Embodied Carbon?", CarbonCure Technologies Inc., 2021. [Online]. Available: https://www.carboncure.com/concrete-corner/what-is-embodied-carbon/#:~:text=Since%20concrete%20is%20the%20most,carbon%20in%20the%20built%20environment. [Accessed: 01- Dec- 2021]

[10] UN News. 2021. Easing ‘classroom crisis’ in Côte d’Ivoire, brick by (plastic) brick. [online] Available at: <https://news.un.org/en/story/2019/07/1043351> [Accessed 1 December 2021].

[11] Critical Concrete. 2021. Tyre Foundations - Critical Concrete. [online] Available at: https://criticalconcrete.com/tyre-foundations/ [Accessed 29 November 2021].

[12] Service.com.au. 2021. How much does concreting cost? | 2020 Cost Guide. [online] Available at: https://www.service.com.au/articles/concreters/how-much-does-concreting-cost [Accessed 15 October 2021].

[13] McHugh, F., 2021. Social housing: Labor demands federal intervention after report warns of 200,000 dwelling shortfall in a decade. The Canberra Times, [online] Available at: <https://www.canberratimes.com.au/story/7408155/stark-warning-over-australias-social-housing-timebomb/> [Accessed 1 December 2021].

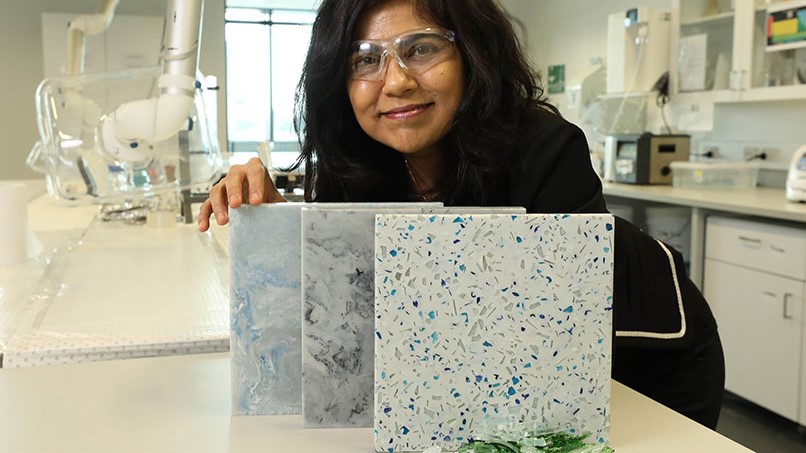

[14] UNSW Newsroom. 2021. Turning old clothes into high-end building materials. [online] Available at: https://newsroom.unsw.edu.au/news/science-tech/turning-old-clothes-high-end-building-materials [Accessed 29 November 2021].

[15] Carpet Recyclers 2021. [online] Available at: <https://www.carpetrecyclers.com.au/used-carpet-tiles?fbclid=IwAR1-14b0qQDZfOzSz9WcZrCCUkjGwQ4raaRMFu3rJMBz69eBIzFse8qn8aQ> [Accessed 1 December 2021].

[16] Floors by Greensborough. 2021. Floorboards Melbourne, Floating Timber Flooring, Bamboo Floor Melbourne, Recycled Timber Floors, Jarrah Floors, Oak Flooring, Engineered Timber Flooring | Floors by Greensborough. [online] Available at: <http://www.floorsbygreensborough.com.au/products/floorboards/?fbclid=IwAR0LqoSEXer42zGnKd7Bi8Mwwcs4iQFWxWQ7bbsjobTC7Q46V6kuqVzxcTs> [Accessed 1 December 2021].

[17] Valencia, N., 2017. This House was Built in 5 Days Using Recycled Plastic Bricks. [online] ArchDaily. Available at: <https://www.archdaily.com/869926/this-house-was-built-in-5-days-using-recycled-plastic-bricks> [Accessed 29 November 2021].